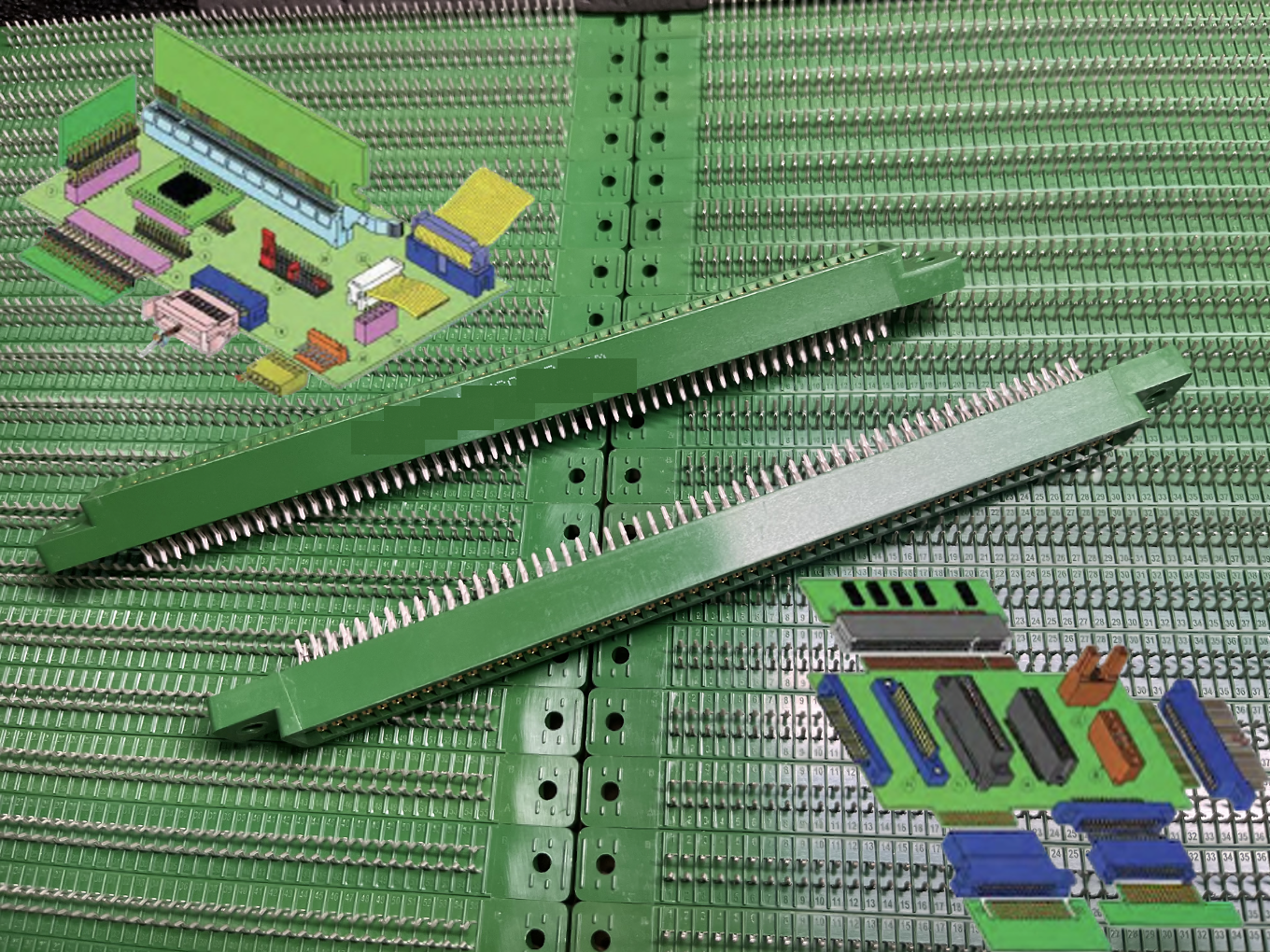

Board-to-board

Card Edge Connectors

SPECIFICATIONS

| Category | Card Edge/Headers/Test Socket |

| Gender | Female/Male |

| Pitch | 1mm/1.27mm/1.98mm/2mm/2.54mm/3.18mm/3.81mm/3.96mm |

| Positions/Contacts | 02~140/02~280 |

| Rows | 1/2 |

| Mating Thickness | 0.79mm/1.57mm/2.36mm |

| Height | 10.95mm/15.49mm/18.29mm |

| Width | 8.13mm/9.40mm/11.94mm |

| Orientation | Strsight/Straddle/Right Angle |

| Termination Method | Card Extender/Dip Solder/Eyelet/Press Fit/IDC/Surface Mount |

| Mounting Feature | Clearance Hole/No Mounting/Side Mounting/#4-40 |

| Operating Temperature | -65 to +125°C~300°C |

| Insulator Material | PBT/PPS/PA9T/PEEK |

| Contact Material | Beryllium Copper |

| Plating [Contact Surface] | Gold, 5μ~30μ" |

| Plating [Termination] | Tin, Matte, 100μ" |

| Card Type | MCA/PCI/ISA/Bi-Level |

| Contact Type | Loop/Hairpin/Full Bellow |

| Tail Length | 2.30mm/4.06mm/5.72mm~19.05mm |

| Current Rating | 1~5A |

| Processing Temperature | 260°C MAX for 20 Sec. |

APPLICATIONS

Communications

Challenge: Design a connector system for a customer to hold a small daughter card in a high vibration environment.

Wireless

Challenge: Reduce the cost of current customer design, where they were doing extensive secondary operations to a card edge connector in order to accommodate components on the daughter card.

Solution: MaLu developed a customized connector with all the modifications the customer was performing implemented into the mold cavity of the insulator, allowing the elimination of all secondary operations the customer was performing.

Semiconductor

Challenge: Design a connector system that allowed for more alignment flexibility in a three connector system, allowed for the use of various board thicknesses in the same system, and allowed the use of more pin-outs within the same space for future expansion.

Communications

Challenge: Design a connector system for a customer to hold a small daughter card in a high vibration environment.

Wireless

Challenge: Reduce the cost of current customer design, where they were doing extensive secondary operations to a card edge connector in order to accommodate components on the daughter card.

Solution: MaLu developed a customized connector with all the modifications the customer was performing implemented into the mold cavity of the insulator, allowing the elimination of all secondary operations the customer was performing.

Semiconductor

Challenge: Design a connector system that allowed for more alignment flexibility in a three connector system, allowed for the use of various board thicknesses in the same system, and allowed the use of more pin-outs within the same space for future expansion.